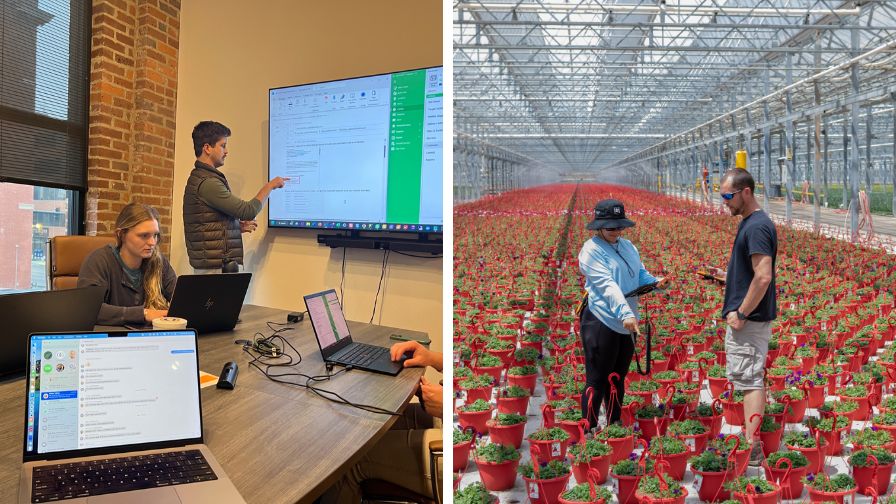

The team at Silver Fern takes pride in knowing they’re building an ERP system that will make life easier for their customers. Here they are at Cultivate’24 (L), and creating a task and knowing your inventory in the greenhouse can be as easy as picking up your smartphone (R). | Silver Fern (L) and Growmentum (R)

Every family wants the next generation to have it better than they did. You don’t have to be physically working in the greenhouse to carry on a family legacy of horticulture. But you do have to understand it. And even better if you’ve lived it.

That’s the case for three software pros today: Adam van Wingerden, CEO of Silver Fern, Marissa Marshall, VP of Business Development at Growmentum, and Garrett Walsh, Horticulture Operations Consultant at Mprise Agriware.

This article was originally intended to highlight the pain points greenhouse growers are facing today, and how various software ERP (enterprise resource planning) programs are helping them. But the deeper we dug into the topic, the more we learned that most everyone has the same issues, and they usually start with production. And maybe even more importantly, with the ever-increasing lack of labor, those driving much-needed efficiencies have agriculture built into their DNA from a long line of growers before them, so they understand the problems on a personal level.

Addressing the Pain Points

The major pain points are the simple ones — not that these are simple by any means:

- Inventory control

- Capacity (or space) planning

- Demand planning

- Replenishment

Van Wingerden, who worked at Color Point for years at his father and uncle’s large greenhouse business, dating back to 1910 in the Netherlands, says, “Our mission at Silver Fern is to redeem horticulture professionals’ time. We lived it,” he says. “Production takes so much time, especially in the spring, because everyone’s just out there grinding. We can give them solutions and tools to help them get their time back so they can spend more time with their families,” he says. “And they have the comfort of knowing there’s a system in place keeping things in order and in check.”

Marshall carries that same passion for wanting to make processes better for growers. Growing up on a large corn, soybean, and Angus beef cattle farm in small-town South Dakota, Marshall says she was immersed in ag from an early age. She takes her experience with prioritizing and executing physical tasks, budgeting, and maintaining accurate financial records, along with monitoring irrigation systems and crop health, and blends that — and so much more — into the commitment and passion she has today for what she does at Growmentum. “This foundation has shaped my perspective on agriculture as a dynamic, innovative, and resilient industry — one that I remain deeply committed to supporting and advancing,” Marshall says.

According to Jackie Lytton, Director of Marketing at Growmentum, the company’s existing grower customers often struggle with the challenge of combining data from various sources to generate specific reports and actionable tasks. She says they’ve found that growers face difficulties in creating forward-looking projections, particularly around labor needs.

“The number-one need we see among growers is the ability to define their technology footprint clearly and integrate systems effectively. This is essential for operating efficiently at scale, improving operational workflows, and collecting high-quality data that drives better decisions,” Lytton says.

Growmentum allows growers to track, down to the second, all of the tasks and activities performed on their crops. | Growmentum

It’s important to note that today’s software programs are not the programs from 30, 20, or even 10 years ago. But the folks in these software companies who are creating these programs stand on the shoulders of generations before them, and they are honored and humbled to do the work they do because they see the benefits these systems can afford growers.

Walsh, a third-generation horticulturist from Central Florida, previously owned his own woody ornamentals and landscape plant business, and his family business has roots in horticulture dating back 70 years. He also grew up with that same passion for understanding what it takes to make a horticultural business run smoothly from an operational perspective. “I’m an operations guy at heart, and I’m at my best when I’m in a greenhouse,” Walsh says.

Understanding Tech Talk

It all begins with a conversation and understanding the grower’s pain points, Walsh says. “We have the ability to do a lot within our software. But often when you’re trying to convince lots of different types of growers to come over to software, there’s this mythical misunderstanding of what it is. My entire role is to shed light on understanding where our software ultimately starts and stops within their process,” he says.

Everyone can agree communication is key. “You have to be out there talking with them [growers] all the time gathering feedback,” says van Wingerden. “Whether it’s talking with the C-Suite, or the director levels, or at trade shows. We’re always out there engaging with our external stakeholders. Then once we obtain feedback, the real work begins as our team goes to work to create the products that address the issues we uncover.”

Technology can be misunderstood. Walsh explains, “Oftentimes what I’ve seen is when we get into a room, a lot of everything we do can still be done with pen and paper, and there’s merit to that,” he says. “So, when I’m addressing these concerns with growers, I try to help them understand those intangible components that really bring value,” he says.

Walsh starts with that pen-and-paper perspective in mind. “I don’t want to overcomplicate things because it’s technical and it sounds fancy,” he says. “At the end of the day, we’re still growing plants. So I try to bring that fact back to square one where the same exact methodology of space planning relates to how they work with pen and paper. We just have that digitally. I need to be able to explain that so growers can see a semblance of that foundational theory,” Walsh says.

Lytton has a similar perspective: “New and potential customers often express concerns about adopting technology. They fear it could create additional work instead of enabling them to do more or better work in less time,” she says. “A key challenge is their lack of understanding of how long specific greenhouse tasks and activities take to complete. This creates a dual issue: 1. Hesitancy about the perceived time and effort needed to utilize a new system; and 2. Stress from tasks not being completed on time due to two distinct challenges — not knowing how much work needs to be done, and ineffective communication about how much work needs to be done.”

Enter AI

And there’s no technical discussion these days that doesn’t include the topic of artificial intelligence (AI).

“AI is a super interesting topic,” van Wingerden says. “I see AI much more as a tool than anything,” he says. “I think those who don’t use AI are going to lose their jobs to people who do use AI,” he says.

Van Wingerden likens AI to the Industrial Age. “When we figured out how to mine coal efficiently, all it did was increase the demand for energy. Same thing with AI. It’s going to increase the demand for quality technology products. So I think that’s really what’s going to happen over the next couple of years,” he says.

If you’re in this industry, there’s no doubt that growing is in your blood. Whether or not you come from a long line of growers, ERP software is slowly making its way through greenhouse operations, and that’s making it more efficient for the next generation.